Table of Contents

If you’re under 50 it’s hard to believe that between the early 1900’s and the 1950s kids skated on metal wheels.

These roller skates were so noisy, that the screeching could be heard a city block away. A small rock or uneven sidewalk resulted in “eating the big one.”

A glacier could beat you in a 5-yard race. Thank goodness the friction between the wheels and pavement prevented you from picking up too much speed — minimizing the road rash on your body.

Not to be outdone, the garage door industry is finally catching up.

Even today, it’s not unusual to find residential garage doors with metal rollers. And just like the old roller skate wheels, they can be unbelievably noisy and when damaged, they can’t roll but rather slide inside the tracks when the door is operated.

A slightly less noisy but still primitive alternative is hard-plastic and rubber wheels. These types of wheels may not use ball bearings reminiscent of axels and wheels found on the riding toy — “Big Wheel tricycle.”

Polyurethane wheels have changed rollerblading and garage door rollers.

A quality nylon garage door roller will have 8-13 ball bearings and are rated between 10,000 and 100,000 door closing and opening cycles.

To put that into perspective, most of the other components of residential doors are rated for 10,000 cycles. The best garage doors may be rated higher.

These new rollers run smoother and quieter. In fact, they can drop the decibel levels by quite a lot and some manufacturers claim a noise reduction of 75% compared with steel and non-bearing rollers.

And if you upgrade from a chain-drive or screw-drive opener to a belt drive opener sold by major manufacturers such as the Liftmaster 85503 MyQ, the noise reduction will be striking.

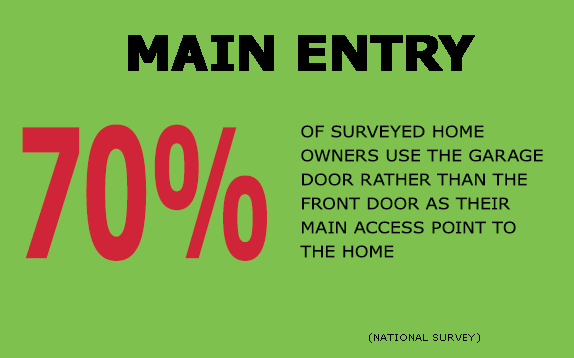

If you’re like 70% of surveyed homeowners who use their garage door rather than the front door as their main access point to their home, this quieter operation is such a small price to pay when the cost is spread over the estimated 10-year lifespan of the upgrade.

What are the best garage door rollers?

The short answer is — it depends.

Materials used to make roller wheels.

Metal wheeled rollers are frequently used with heavy industrial doors where durability, load capacity, and other factors make them the best choice.

Also, if longevity is the primary consideration, steel rollers are by far a better choice over nylon, rubber, or other alternatives.

Vinyl wheels offer superior noise reduction when compared to steel wheels.

Vinyl garage door rollers come with different weight capacities. Typically, there is a correlation between the number of ball bearings and their load capacity. Also, the higher the load capacity, the longer the life expectancy of the roller.

It should be noted that vinyl is used to cover the exterior of the steel substrate that comprises the steel foundation of the roller wheel. The roller components are similar to those of a car wheel. The foundation is always metal starting with the bearings, then comes the rim to which the rubber tire is mounted. Think of the vinyl as the rubber tire.

Materials used to make other roller components

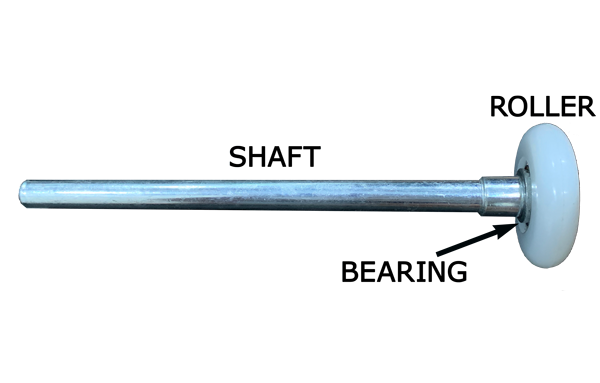

The other parts that comprise a complete garage door roller including the shaft, the ball bearings, and the inner and outer rings, and the cage. These parts are typically metal.

In some instances, the metal components are manufactured from stainless steel or they may be zinc plated for protection from corrosion. Plated steel is useful in instances where the doors are exposed to salty conditions such as homes located near an ocean.

Plastics may be used as a shield as in the case of sealed bearings. In some instances, other seals are present, and these seals can be constructed from a variety of materials.

Finally, the bearings should be lubricated.

As mentioned earlier, sealed rollers are a great way to prolong their useful life. As the name implies, the seal retains the lubricant for a long time.

More importantly, the seal prevents dust and grime from mixing with the lubricant. When there is a buildup of foreign materials, the lubricant loses its effectiveness and turns into a gritty sludge that can actually mar the surface of the bearings and the housing.

What type of lubricant should be used for garage door rollers?

NEVER use regular WD-40 to lubricate garage door rollers! This product is specifically formulated to loosen rusted parts and is not made for lubricating bearings. In fact, WD-40 causes the bearings to dry out.

Instead, use a lubricant specifically formulated for garage doors. These products are sprayed on moving parts providing high adhesive strength that initially goes on thin and then immediately forms a viscous grease that stays put. These products can be purchased at a home improvement center or online.

Cleaning bearings is a topic for a whole separate article. However, if you feel that it’s worth your time and effort to clean the bearings, do a search on Google or YouTube to see what others have done. Personally, I would prefer to replace the rollers because they are so inexpensive.

If the bearings are not sealed, semiannual lubrication of the rollers and other moving parts is recommended using the specific lubricant made for garage doors. A good memory trigger is when daylight savings starts and ends. This is also a good time to change out the batteries on your smoke alarms.

How are garage door wheels connected to the garage door?

Rollers don’t float in the air. They are attached to the door by way of hinges. Hinges may contain two tubular shapes. One tube is the actual pivot point of the hinge, and the other is where the shaft of the roller is inserted. Hinges are numbered to match the angle of each panel as it transitions from its vertical to horizon position when the door is operated.

The shaft fits loosely inside the tube allowing the garage door wheel to remain inside the track as the door shifts left and right when the door is operated. Otherwise, if there was a rigid connection between the shaft and the hinge, the rollers would disengage from the track causing the door to go “off-track.”

The best garage doors which are typically heavier doors and wind-load doors require dual or tandem hinges which are mounted on double end stiles.

Stiles are used in sectional garage door panels to support roller brackets, hinge assemblies and lock sets. Stiles along with support channels (struts) function like the skeletons in our body. They provide the foundation and structure to which the muscles (springs, cables and rollers) are attached. The skin of the door are the actual panels — which like our skin is relatively thin and fragile without the underlying skeleton.

When dual hinges are used, long stem rollers are used to stabilize the door as it opens and closes. The long stem rollers vary in length and typically have 7” axels and extra-long stems have a 9” length.

The track, which provides stability and guides the path of the rollers, is composed of a vertical and horizontal section on each side of the door. Where the two sections meet often creates an area for potential problems. If the sections are not aligned, a gap or ridge can cause the rollers to stick or rub. This can potentially cause the door to go off-track or result in premature wear to the rollers.

When operating the door with an opener, the motion should be smooth and uninterrupted. If the door jerks or surges and if you hear popping noises, most likely there is a problem with the track alignment.

The tracks must be installed so that they are parallel with the door and to each other. If one is mounted slightly higher than the other, pinching of the door frequently occurs.

Like all garage door components, tracks come in a variety of quality. The steel strength and gauge and the details addressed during the manufacturing process all play a vital role in the overall quality of the track.

Garage Door Roller Replacement: Should you replace one, several, or all the garage door rollers?

In most instances, the rollers were installed together. Therefore, if one or two are worn out or damaged, it is logical to conclude that the other roller will soon follow suit. I’ve already stated my preference to replace all the rollers because the parts cost far less than paying a professional’s trip charge or your time to run to the store in the event you’re doing a DYI project.

How long does it take for garage door roller replacement?

What might take you several hours, including finding the right garage door wheels, ordering them online or running to the store, learning how to replace the rollers safely, etc. can be done in minutes by a professional.

You might feel that the technician is price gouging you when you compare the time it takes versus the price of the service. But you might feel different when you’re in the emergency room because you loosened one of the rollers under full tension (more about safety later).

Knowing how — takes a lot of experience, knowledge, and the right tools. It reminds me of the parable of the old engineer.

CAUTION — How to avoid injury doing garage door roller replacement.

If you’ve heard this once, you’ve heard it a hundred times. Normally the garage door is the heaviest moving object in a home. It’s not unusual for a door to weigh several hundred pounds. The best garage doors are reinforced and can weigh even more.

Without the lifting power of the springs, it is nearly impossible for one or several people to lift a closed door with their bare hands.

In fact, the primary job of the springs is to neutralize the weight of the door at every stage of opening. To test whether your springs are doing their job, simply disconnect the emergency release by pulling on the cord on the rail attached to the door and your opener.

Now you should be able to lift a 16’ x 8’ door with one hand. Lift the door a few feet at a time and release your grip on the door at each level. The door should remain in place. It shouldn’t close or open. If it wants to crash down or race up at high speed, you have a spring issue and you should call a professional to address it. In the trade, we call it “heavy” if it wants to close and “hot” if it wants to open.

Both “heavy” and “hot” doors can lead to all kinds of issues. To prolong the life of the opener and door components, it is essential that the door is properly balanced.

All the forces working on the door are transferred via two relatively thin (1/8”) steel cables that are attached to drums secured to a torsion tube (in the case of a torsion spring setup) or directly to a pair of extension springs.

The other end of the cable is attached to the bottom bracket on each side of the door. That bracket also houses the bottom garage door wheels.

So, you must release the force on the bottom cables attached to the bottom roller before attempting to remove the bottom bracket to avoid injury.

Remember that those cables are designed to carry the full weight of the door and releasing that energy abruptly can cause serious injury.

What are the criteria for selecting the best garage door rollers?

Garage Door Roller Material

- Metal – the strongest and most durable material, it is the choice for heavy commercial doors where noise is not a major concern.

- Vinyl – the choice for those who want a quiet door. Currently, plastics are not as durable as metal. However, product improvements have increased the lifespan ten-fold over earlier versions. It’s the best method to eliminate operating noise when used in conjunction with a belt-drive opener with DC motor.

Roller Sizes

Most residential doors come with 2” rollers and a 4” stem. Heavier duty situations may call for larger diameter 3” wheels and longer stems which are normally 7” or 9” in length. Other lengths exist, but they are rarely used.

Rollers must match the track width. For example, 2” rollers are in fact slightly smaller in diameter. This provides just enough free play — approximately 1/8” — between the roller and the track yet not too much preventing the roller from popping out of the track.

Garage Door Roller Ball Bearings

Ball bearings are used in several places throughout the door system.

Aside from the roller’s ball bearings, they are found inside the left, center and right bearing plate in a torsion spring system. The fact that these bearing locations are not well known — even among “professionals” — causes the lubrication of these critical parts to be overlooked.

This can lead to a situation where the torsion tube is unable to rotate freely as the door is operated resulting in all sorts of complications including damage to the opener as-well-as other components.

Whenever torsion springs are replaced, these bearings must be inspected and if damaged, they should be replaced.

Bearings are also present with extension spring systems. These are called cable pulleys and they too must be lubricated on a regular basis.

Garage Door Roller Weight Limits

The number of ball bearings inside rollers can determine the amount of weight they can carry. More balls in the bearings can also result in longer bearing life. Quality rollers have between 8 and 13 balls

Garage Door Roller Lifecycles

Garage door components are typically rated based on cycles. Standard torsion springs are rated for 10,000 cycles and so are basic vinyl rollers. Depending on the use of your door, that equates to approximately 10 years of typical use.

Garage Door Roller Shaft

Garage door roller shafts come in a variety of lengths and materials. Zinc plating is recommended when the door is near the ocean to prevent corrosion.

Garage Door Roller Colors

There’s not much to say about color choices since they are basically limited to either metal, black or white.

ServiceBasix Garage Door Roller Repair

The garage door roller is an essential component of a well-functioning garage door. Most people are unaware of the impact of broken or damaged rollers have on their door. While everyone understands the need to change the oil on their car, virtually nobody understands the need to lubricate the bearings and other moving components of their door — including the rollers.

Here at ServiceBasix Garage Doors, our garage door technicians are highly trained on garage door roller replacement. With just one call, we can assist you with your roller repair! Contact us at 512-953-3338 to schedule a garage door repair with us!

Schedule Garage Door Roller Replacement with ServiceBasix!

Frequently Asked Questions

First, in most instances, it is best to replace all the garage door wheels. Labor is the biggest cost factor in changing out a garage door roller.

That being said, depending on the area of the country and the number of rollers your door requires, we charge in the range of $75 – $90 for parts and labor.

Market rates are between $100 to $150. In any case, be wary of “Bad Bobs” as the International Garage Door Association (IDA – www.doors.com) refers to rip-off artists who frequently charge hundreds of dollars for this service.Here at ServiceBasix, we offer a fair wage

If all the conditions are correct, our experienced garage door technicians can be replace your garage door roller in 15-20 minutes. In some more difficult circumstances, each hinge must be disassembled to remove and replace the rollers. In such circumstances, it may take to up to 45 minutes.